UNI Metal Door & Window Frame

UNI Metal Door & Window Frames are made using Electro-Galvanized Steel or Galvanized Iron Steel. UNI Metal Door & Window Frames will not rot, warp, twist or suffer from insect attacks. Manufactured to perfection our Metal Door & Window Frames comes complete with built in hinges, doorstops and architraves. The UNI Metal Door & Window Frames becomes an integral part of the wall and hence adds to its strength. UNI Metal Door & Window Frames gives you the flexibility of integrating with feature face brick or plastering and made to the exact requirements of the door for which they are intended. We include all parts where required to install the door frames together.

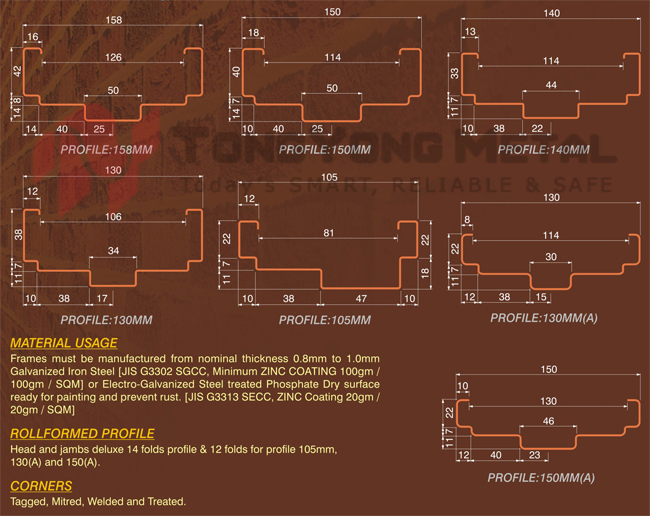

Manufacturing Process:

1. The frames must be roll formed and not pressed to ensure consistent profile which includes 14 bends, 2 of which have a radius of 6mm and from part of the architrave.

2. The profile must be uniformed so as to ensure a good quality finish to the welded and tagged corners which form a part of the structure requirements of the metal frame.

3. The jambs and head section are to be mitred after the roll forming process.

4. The jambs and head to be mechanically fixed together by tabs which protrude through the head section and are folded flat towards the outer edges of the jambs.

5. The head section is to be made in such a manner that it will pass over the jambs at either sides by approximately 30mm to stop cement and debris from being visible when frame installed.

6. The jambs to be slotted to receive hinges in 3 positions.

7. The hinges, which form part of the frame unit, are specially produced suitable for projection welding and are fused on the frame in one operation. Spot welding is not acceptable and must not be used.

8. The stricker plate slot to be opposite side of the hinged jamb is also produced after roll forming. It then is covered at the rear by a G.I. mortar guard to allow for the cylinder lock to protrude past the jamb and not allow debris or bricks to be visible or interfere with lock cylinder.

9. When all hinges and stricker plate have been installed, the components are held together with pneumatic controlled jigs to ensure consistent size and squareness to each and every frame.

10. After positioning of frame components into jig, welding is to take place to the four external corners only without being removed from jig until welding has been completed on all four sides and the spreader bar at the base of the frame has been installed by bending the tags provided.

11. Upon removal of the frame from welding jig, it is then ground flush and smooth and painted with zinc rich primer within 8 hours of grinding. It is then checked for imperfections by Q.C. and tagged either with red stickers to hinges to indicate a door opening towards you and being left hand hinged door or green stickers indicating door opening towards you and indicates right hand hinged door.

12. Each frame delivery will include wire ties for use in building into brickwork. 4 wire ties and 3 adaptor strap per DOOR frame to be supplied. 8 wire ties per WINDOW frame to be supplied.

13. There is NO lintel require for frame width 1 m, and after fifth course of brickwork, please remain for setting at least 24 hours, the rest brickwork to be continued.

Specification | Light - 0.8mm Std - 1.0mm

Others:

Metal Door Frames Hardware |

Installation Process |

KD-System |

Project Reference:

View More

View More

Download our brochure:

Go Back Back to Top